Sometimes, a single epiphany is all it takes to spark a dream. This was the case for Sanjeev Sehgal, an electronics engineer, during a client visit for a CCTV installation. That moment set him on the path to entrepreneurship.

“The client was frustrated seeing the CCTV cameras tethered to bulky systems on office desks via lengthy cables sprawled all over the floors and tables. It was at this time that an idea sparked in my mind and my entrepreneurial journey began in 2002,” Sehgal reminisces.

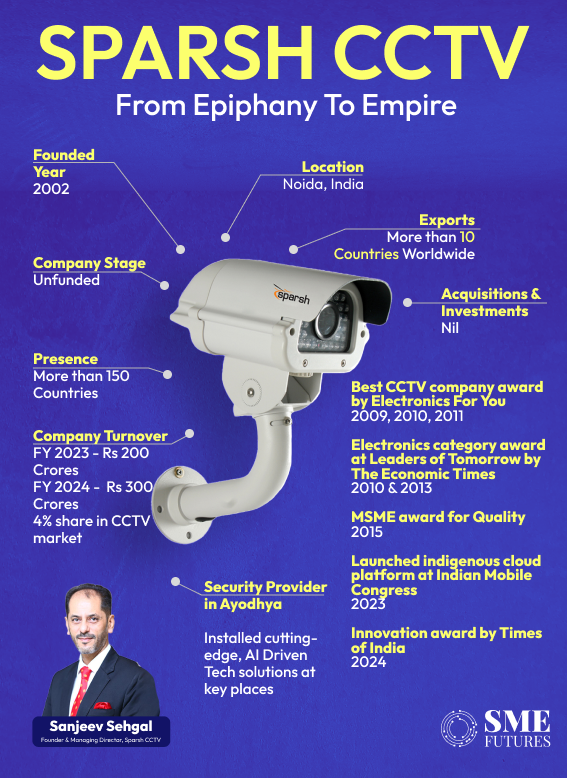

Today, he is the Founder and Managing Director of Sparsh CCTV, which has the second largest turnover in the Indian CCTV market. With a pioneering spirit and a commitment to quality, Sparsh CCTV has revolutionised the Indian electronics manufacturing landscape.

Currently, Sparsh CCTV holds about 2 per cent of the Indian market share. Due to the new policies and initiatives, Sehgal projects significant growth. This year they are confident of achieving 5 to 7 per cent of the market share and going forward in the next 2 to 3 years are eyeing to be the leaders in this domain. “We expect to garner a minimum of 30 per cent market share in the next three years,” he predicts.

From manufacturing to exporting

The company has three state-of-the-art manufacturing units in India, and has over 200 SKUs, which range from basic CCTVs to accessories to advanced AI and IoT solutions. Furthermore, Sparsh was the first domestic brand to pioneer remote operating switches for CCTV cameras. Also, they were the ones who first started making AV door phone systems and intruder alarm systems in the surveillance arena.

Unlike many others in the industry, Sparsh CCTV did not start as an importer. Instead, they started from manufacturing and then began exporting. One of their primary challenges was the absence of an ecosystem for electronics and hardware manufacturing in India. Competing against Chinese products, which dominated the market, posed significant hurdles.

Even today, most of the components and products are being imported from China by the players in the CCTV space. However, Sparsh CCTV has achieved more than 70 per cent domestic value addition by manufacturing in India. Sehgal proudly notes, “In the next two years, we aim to design System on Chip (SOC) in India.”

Meanwhile, Sparsh CCTV’s expansion into the global market began a few years ago.

“During the G20 summit, we announced an MoU with Dast, a Saudi Arabian company, where we will be the technological partner for their manufacturing unit,” Sehgal explains. The company has also established a presence in Canada, the United States, Bhutan, Rwanda, and soon, Nepal. “We are setting up an assembly unit in Canada and have an office in the United States, with more tie-ups on the horizon,” he says.

Today the company exports to more than 10 countries and is present in more than 150 cities in India.

Enhancing security in Ayodhya

Recently, Sparsh CCTV played a pivotal role in enhancing security in Ayodhya with its cutting-edge, AI-driven technologies. It’s one of the key milestones for the company, says Sehgal.

“We successfully installed Cyber Secured Hi-Tech CCTV cameras at strategic locations like temple entrances, Ayodhya Dham railway station, car parking spaces, and key entry points into the city,” Sehgal shares. These advanced cameras offer real-time facial recognition, behaviour analysis, anomaly detection, automated alerts, and smart parking solutions with number plate recognition, providing unparalleled precision and efficiency in surveillance.

In October 2023 at the “Indian Mobile Congress” summit, Sparsh launched an indigenous cloud platform providing integrated solutions. It presented 20 5G use cases like facial recognition & railway driver alert systems for railways and airports, intelligent traffic monitoring systems for roadways, explosion proof cameras for mining & ONGC, thermal cameras for defence & body worn cameras for law enforcement.

Additionally, Sparsh CCTV’s commitment to quality and innovation has been recognized with several prestigious awards, including the MSME Award for Quality by PM Narendra Modi in 2015; the Electronics Category Award at Leaders of Tomorrow by The Economic Times (2010, 2013); the Innovation Award by Times of India (2024); and the Best CCTV Company Award by Electronics For You (2009, 2010, 2011).

Impact of “Make in India” and industry standards

There was no clear policy for CCTVs until a few months ago. The government’s basic thought process was to promote domestic manufacturing for government procurements. However, the “Make in India” initiative has provided a substantial boost to companies like Sparsh CCTV.

“There has been a complete change of thought process, and Indian companies are now considered as good as the overseas players. Under the Make-in-India policy of DPIIT, the essential requirements to be filled up related to cybersecurity and a trusted value chain,” says Sehgal.

A similar policy was initiated by the railways two years back, and Sparsh CCTV was the first company to get IoTSCS (STQC) certification for any IoT (CCTV) product. According to Sehgal, the new policy will restrict imports from neighbouring countries and Indian companies will get preference in government procurement orders.

Sehgal has also played a key role in setting industry standards. He is the founding chairman of the Security Promotion Group of India (SPGI) and is the convener of the Video Surveillance Committee on Indian Standards at BIS.

“A decade ago, low-quality equipment import flooded the Indian market. We first created a basic ecosystem and then we worked on setting safety and performance standards,” he asserts. Recently, cybersecurity standards have become essential, reflecting the evolving needs of the industry.

“Cybersecurity is as an essential requirement under the Public Procurement Order and the Compulsory Registration Order. We have gone through a complete cycle of standard formation for standardising products which have to be sold in India under the CCTV domain,” he emphasises.

Industry initiatives for growth

According to Sehgal, the new policies that have been initiated must be implemented well at the ground level. When that happens, homegrown companies like Sparsh CCTV will benefit immensely. “There is a huge opportunity not only in India but also globally for surveillance equipment. The recent policy of the government will give domestic players like us a phenomenal push,” he notes.

Looking ahead, Sparsh CCTV has ambitious plans for growth. The company is developing an electronics manufacturing cluster in Kashipur, Uttarakhand, with the capacity to produce one million cameras per month. “This unit will have backward integration with most parts being manufactured in-house with cost optimisation and compete with Chinese products,” he asserts.

Sparsh CCTV’s journey from a small entrepreneurial spark to a leading player in the video surveillance industry exemplifies the potential of Indian manufacturing. With a focus on innovation, quality, and global expansion, Sparsh CCTV is poised for continued success in the years to come.