It’s hard to believe, but it’s been 10 years since the launch of the ambitious Make in India initiative. On September 25, 2014, Prime Minister Narendra Modi announced a plan that would soon become one of the nation’s most significant drivers of industrial and economic growth. The goal? To turn India from a mere consumer into a global producer and ensure that the world recognised Indian products not just as imports but as quality exports. Fast forward to 2024, and India has indeed made its mark on the global manufacturing landscape.

What Make in India set out to achieve

When the Make in India initiative was conceived, the country was facing a challenging economic landscape. The initiative aimed to spur growth by creating an environment where both domestic and international businesses could thrive. It wasn’t just about economic recovery but about reshaping India into a global manufacturing hub by focusing on several pillars:

- New Processes: Simplifying regulations to improve the ease of doing business.

- New Infrastructure: Building industrial corridors and smart cities.

- New Sectors: Expanding foreign investment in critical sectors such as Defence, Railways, and Renewable Energy.

- New Mindset: Shifting the government’s role from regulator to facilitator of business.

The goal was not just to focus on traditional industries but also on emerging ones like biotechnology, aerospace, and renewable energy. The initiative also aimed to generate jobs and boost India’s workforce capabilities, especially in sectors like textiles, automobiles, and electronics.

The growth of manufacturing in India

Ten years in, India’s manufacturing sector has made remarkable strides. The country is now the second-largest mobile phone manufacturer globally, and its electronics sector alone hit $155 billion in FY23.

But this isn’t just about mobile phones. The Production Linked Incentive (PLI) Scheme, launched as a part of the Make in India initiative, has covered 14 key sectors including medical devices, food processing, and high-tech electronics. The PLI has attracted ₹1.23 lakh crore in investments, creating over 8 lakh jobs.

Moreover, India’s defence sector has seen a sharp rise in self-reliance. The INS Vikrant, the country’s first domestically made aircraft carrier, is a clear testament to this. Defence production hit ₹1.27 lakh crore in 2023-24, and India is now exporting its defense equipment to over 90 countries.

And who could ignore the Vande Bharat trains? These indigenous high-speed trains are rapidly expanding across the country and have set a new benchmark in India’s engineering capabilities.

Foreign investment and India’s growing global appeal

Since 2014, foreign direct investment (FDI) inflows into India have grown substantially, with a total of $667.41 billion received between 2014 and 2024. FDI rules have been simplified across sectors like insurance, railways, and defense, making India an attractive destination for global investors.

This surge in FDI is particularly notable in sectors like renewable energy, where India has positioned itself as a global leader. With PM GatiShakti, India is investing heavily in developing multimodal infrastructure, improving transportation, and reducing logistics costs, all aimed at achieving the nation’s goal of becoming a $5 trillion economy.

India’s big wins: Semiconductors and electronics

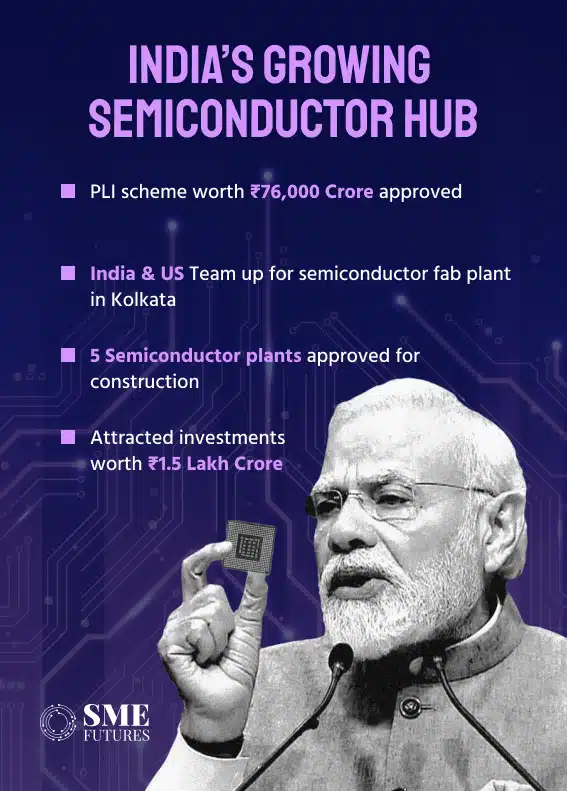

In 2021, India made a significant commitment to build a semiconductor ecosystem with the launch of the Semicon India Programme. With an outlay of ₹76,000 crore, this initiative aims to attract capital support for semiconductor fabs, packaging, and display technologies.

The first major win under this program was the approval of Micron’s ₹22,000 crore semiconductor project. Additionally, Tata’s joint venture with Taiwan’s Powerchip for a project in Dholera is further proof that India is no longer just a consumer of high-tech products but an emerging producer. These efforts are set to boost India’s position in the global supply chain for critical electronic components.

The cultural and social impact of Make in India

One of the more unexpected outcomes of Make in India has been its social impact. Beyond industry and infrastructure, the initiative has encouraged a revival of traditional Indian crafts on the global stage. From Bihar-made boots making their way into the Russian army to Kashmir willow cricket bats becoming a global favorite, Indian products are now earning recognition for their quality and craftsmanship.

Additionally, the textile industry has created a whopping 14.5 crore jobs, significantly boosting employment and livelihoods across the nation.

Challenges and future prospects

While Make in India has undoubtedly driven significant progress, it hasn’t been without challenges. For one, India’s manufacturing contribution to GDP remains around 17 per cent, far below the target of 25 per cent initially envisioned in 2014. Moreover, the global economy continues to face headwinds, including supply chain disruptions and geopolitical tensions, which could impact future growth.

That said, with a renewed focus on green technologies, clean energy, and cutting-edge innovations like hydrogen fuel cells, the future looks promising. The government’s commitment to continuing reforms, coupled with India’s young and talented workforce, ensures that the next decade could see India emerge as a global powerhouse in more than just one sector.

As Make in India marks its 10th anniversary, it’s clear that the initiative has transformed the nation’s industrial landscape. From defense production to mobile phone manufacturing and renewable energy, India is becoming increasingly self-reliant and globally competitive. The world is not just watching—it’s partnering with India, as businesses look to India as a vital player in the global manufacturing ecosystem.

As Prime Minister Narendra Modi put it, “Bharat is unstoppable.”